The year 2020 is coming to an end and it is prudent to take time to reflect on the state of life, the universe, and everything on the final day of the year.

It has been an interesting year in many ways – some good news and some challenges.

Robotics

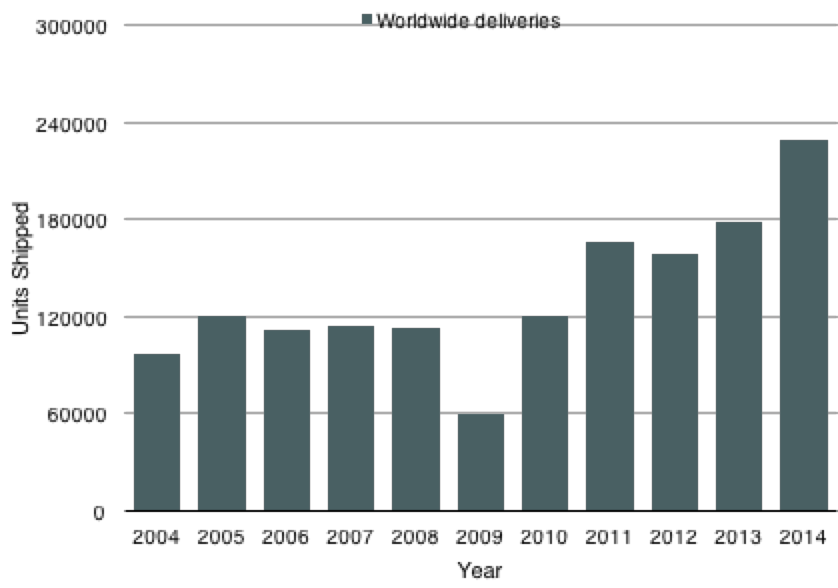

The world of robotics has generally done well. The pandemic has accelerated the adoption of e-commerce and home delivery. The pandemic has also made the need for tele-robotics much more obvious. We have seen new use-cases such as robot disinfection, which 12 months ago was considered exotic, and now it is obvious as a business case (not clear for how long).

Logistics

One of the clear winners during COVID was the need for more streamlined supply-chains. Early on in the pandemic, there was a massive shortage of toilet paper (of all things). Later a number of other things went missing for short periods of time. Home delivery from companies such as Walmart and Amazon became an everyday business.

Amazon used to have almost half of the e-commerce sector but the market share reduced to 1/3 during 2020, as more and more retails entities entered the space (Digital Commerce 360, 2020)

Service-based food delivery, such as Grubhub, and Doordash, was suddenly entirely normal just as Americans used to go out to restaurants now they were ordering food from their favorite restaurants for home delivery.

Obviously, supply chain was also a key item for delivery of vaccines to hospitals and to ensure that testing for COVID could maintain its efficiency. Multiple places had COVID testing with results returned in 15-20 hours. Some places also started to do wastewater testing for pooled testing (UCSD, 2020). Overall the biomedical sector saw significant growth.

The big push in e-commerce was bad news for local neighborhood stores. As an avid Yelp reviewer many of my regular places closed, and in many cases for good.

Manufacturing

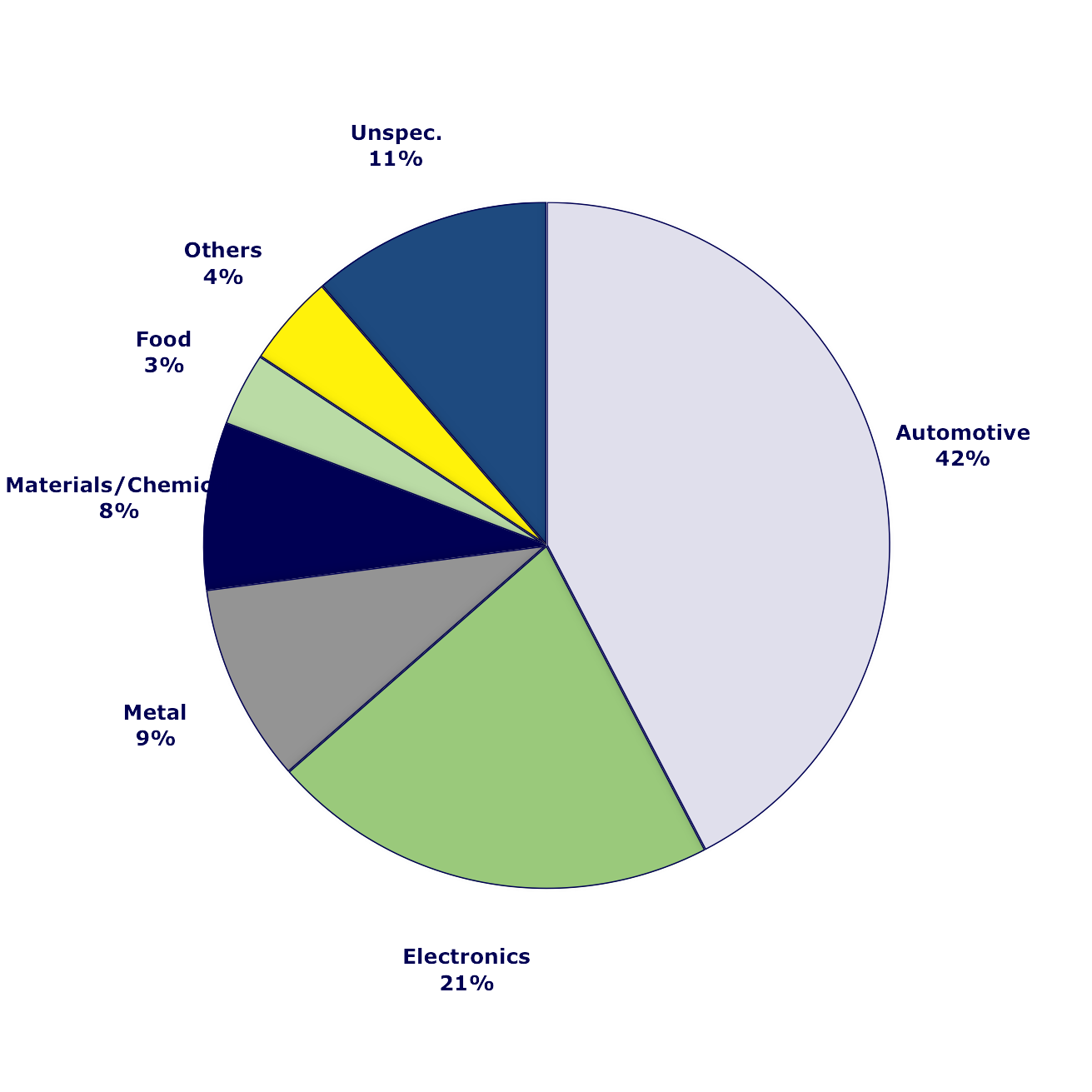

The economic downturn that started in late 2019 progressed into early 2020. The sector saw a reduction that was on par with the downturn during the 2009 recession (FRED, 2020). Many areas saw a relatively quick recovery. However, some areas such as automotive experienced a major downturn. Multiple automotive companies reported a 50% decline in revenue. Overall manufacturing is at the same level as it was in January 2016.

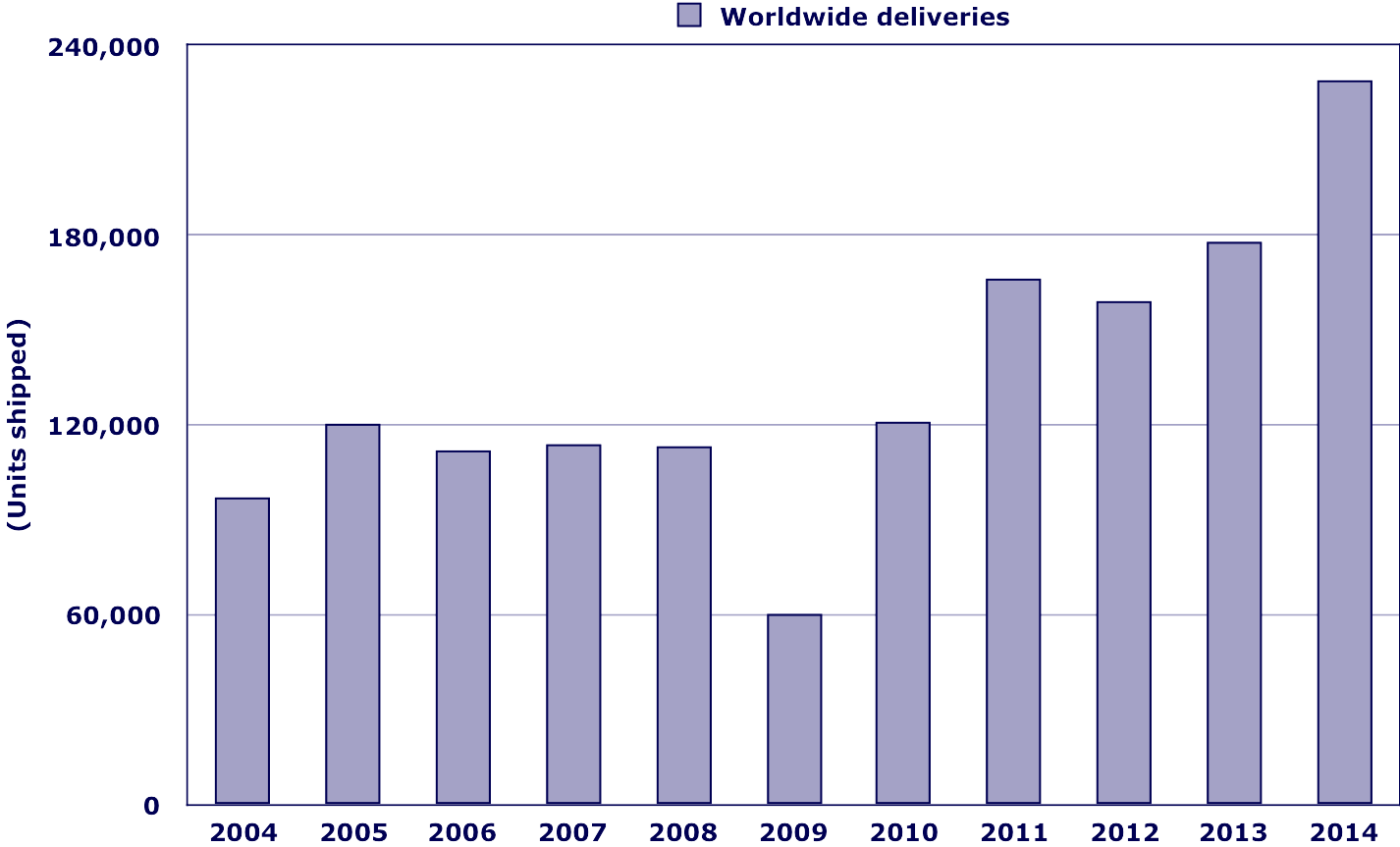

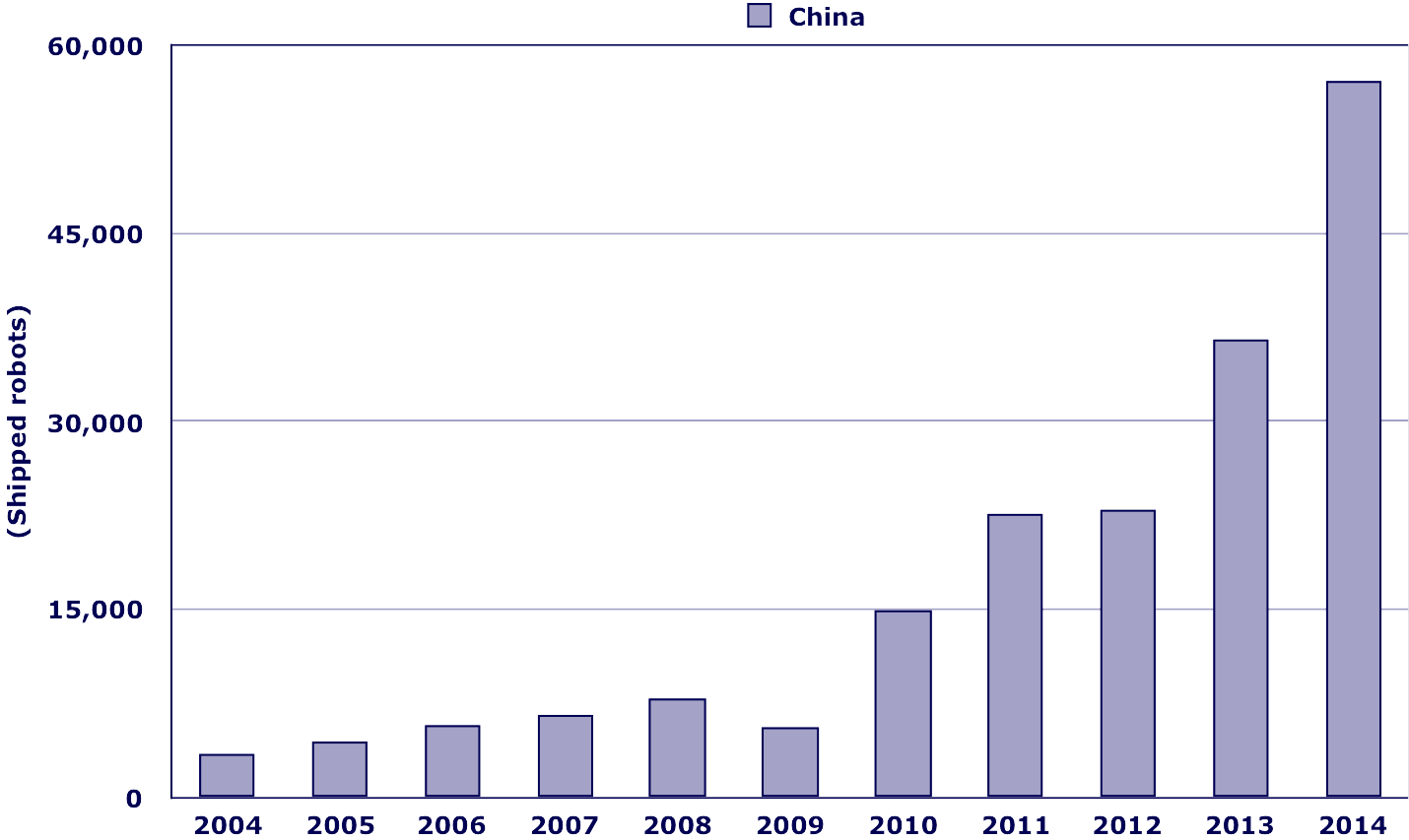

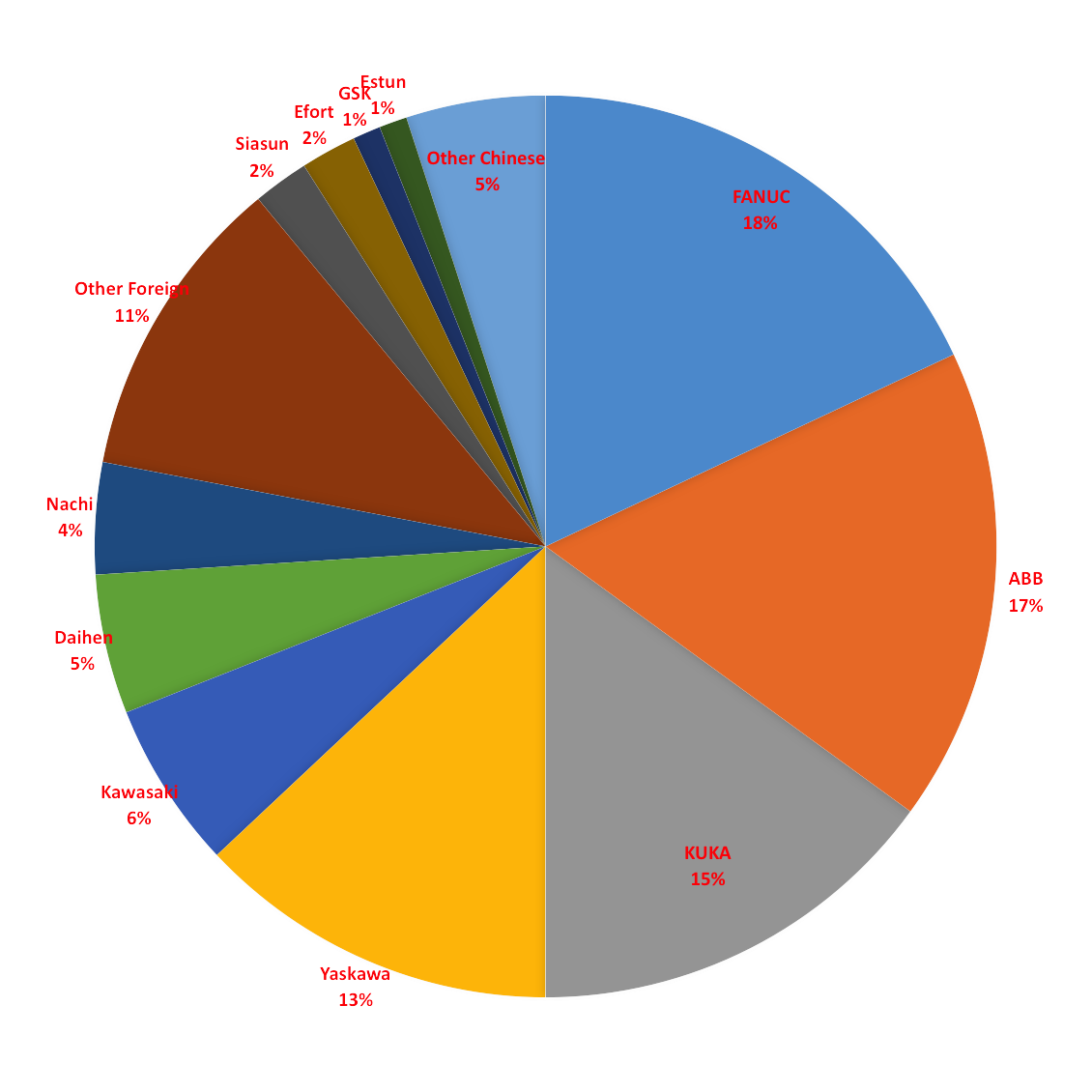

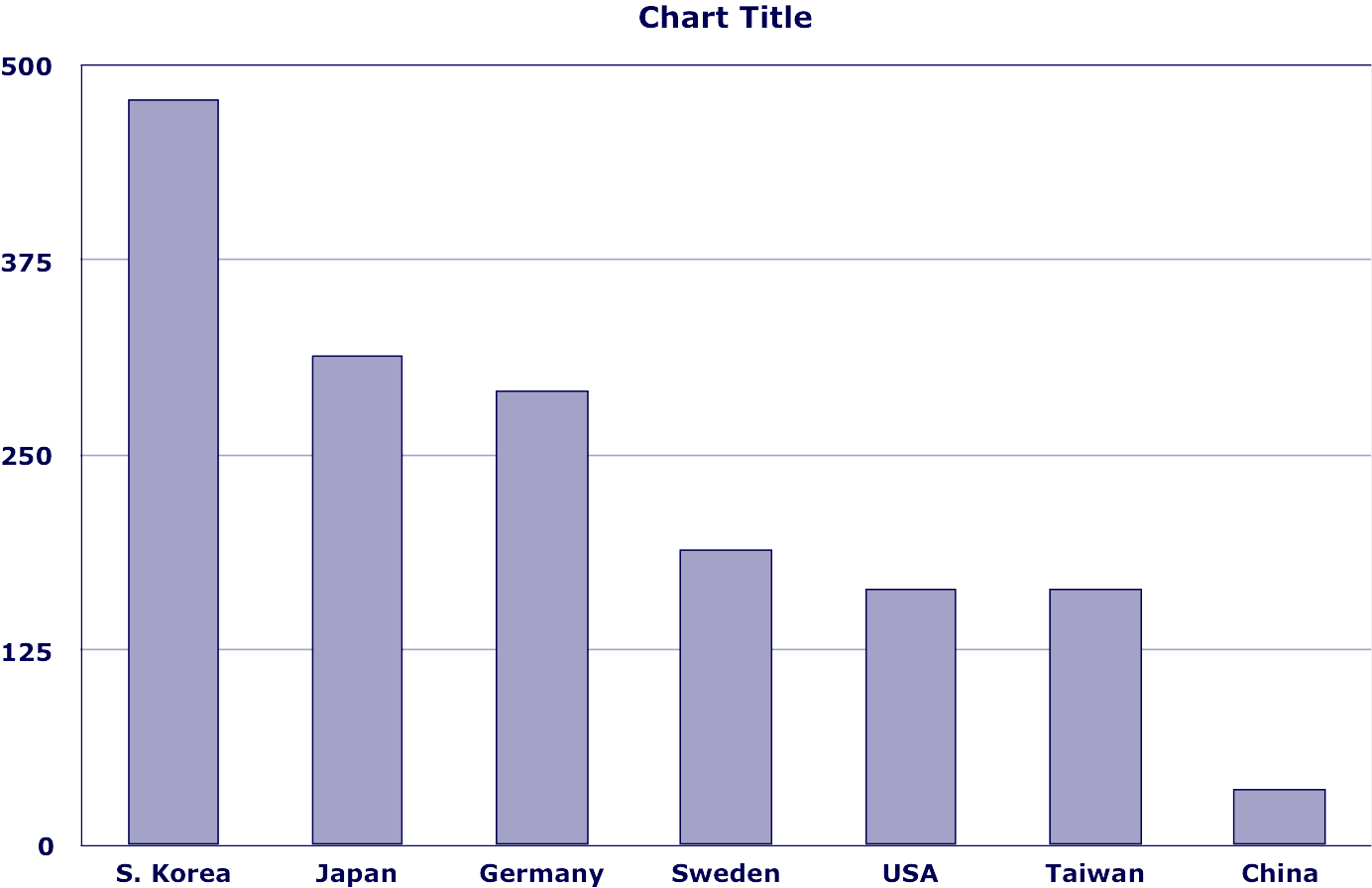

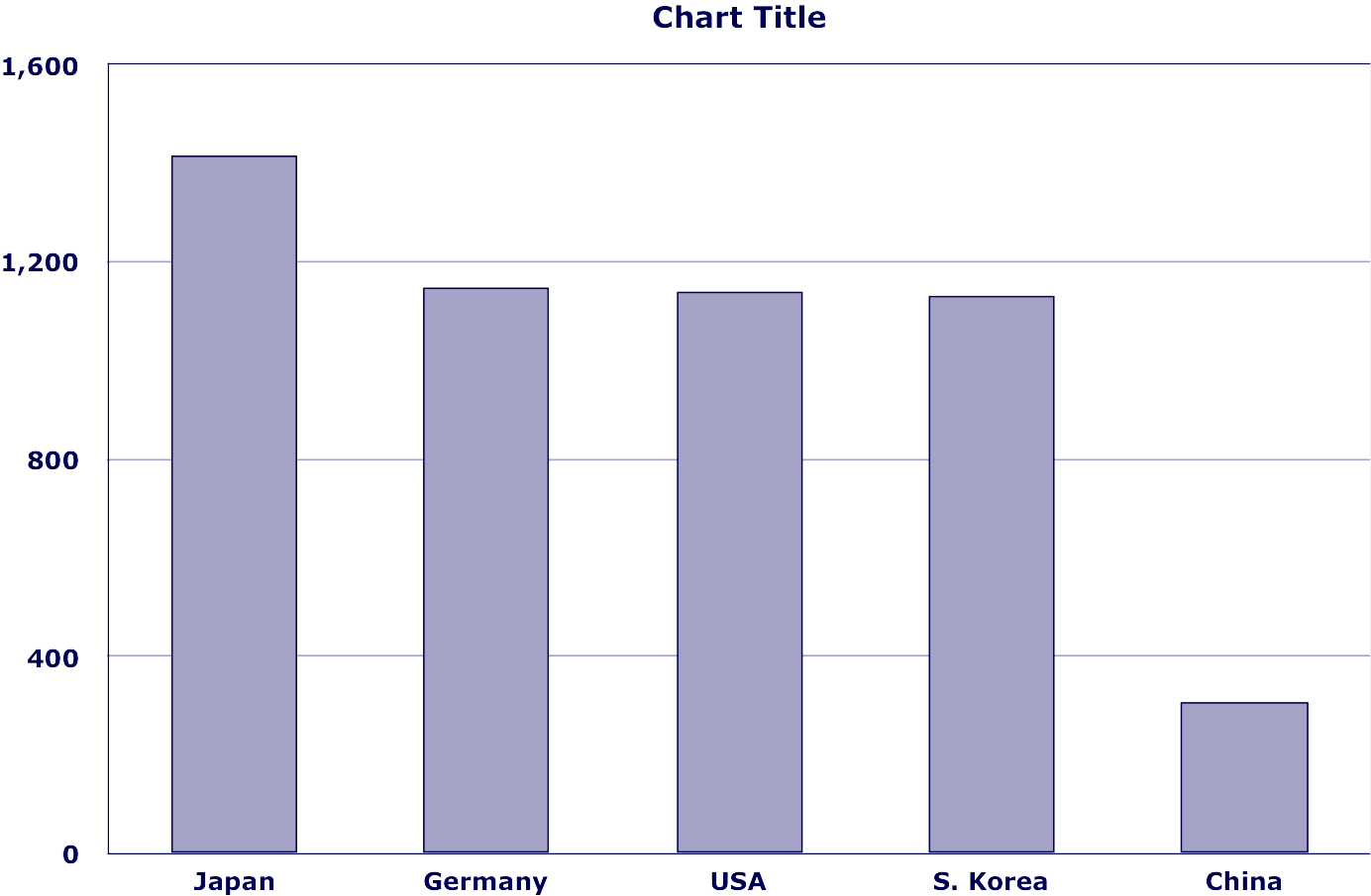

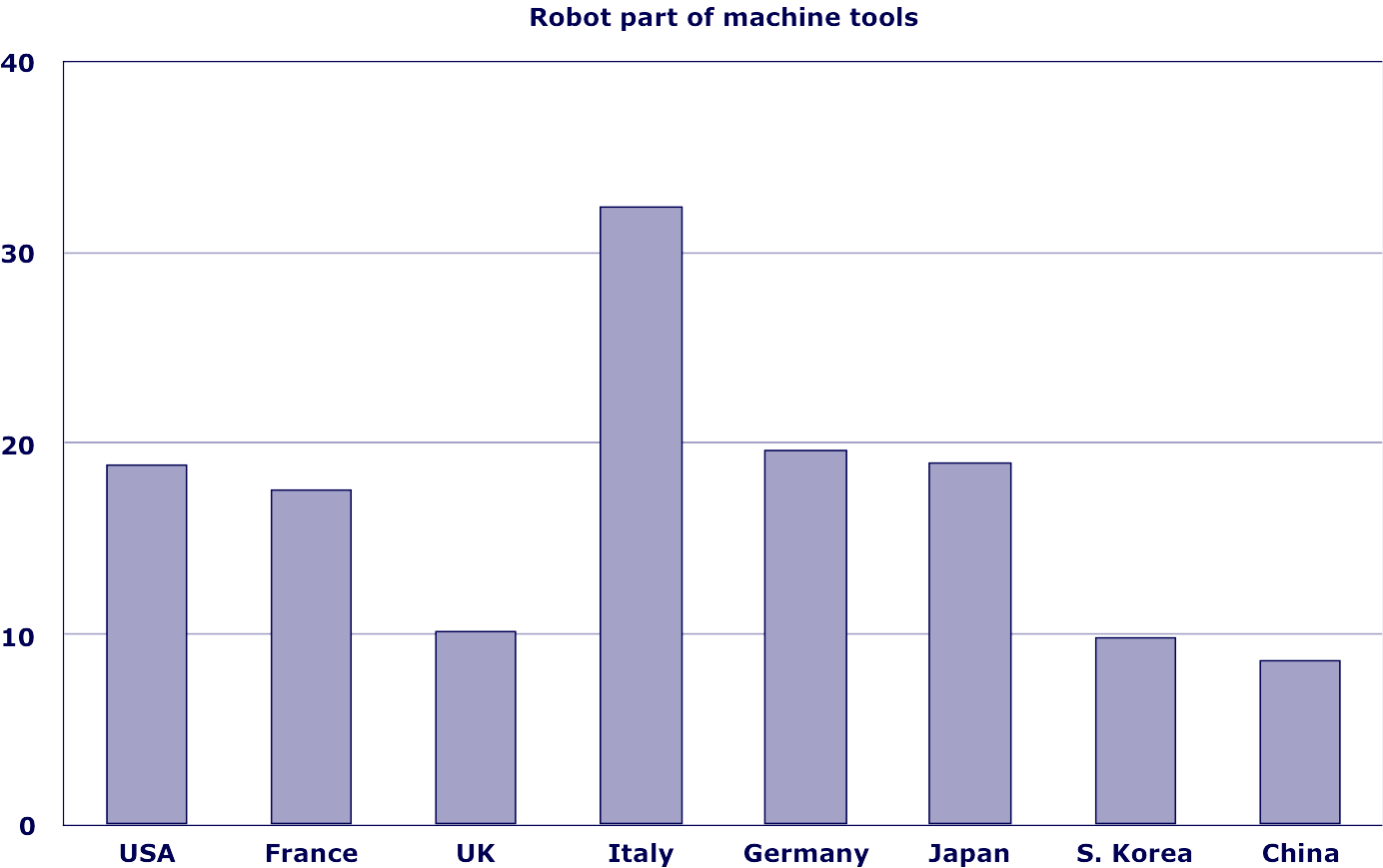

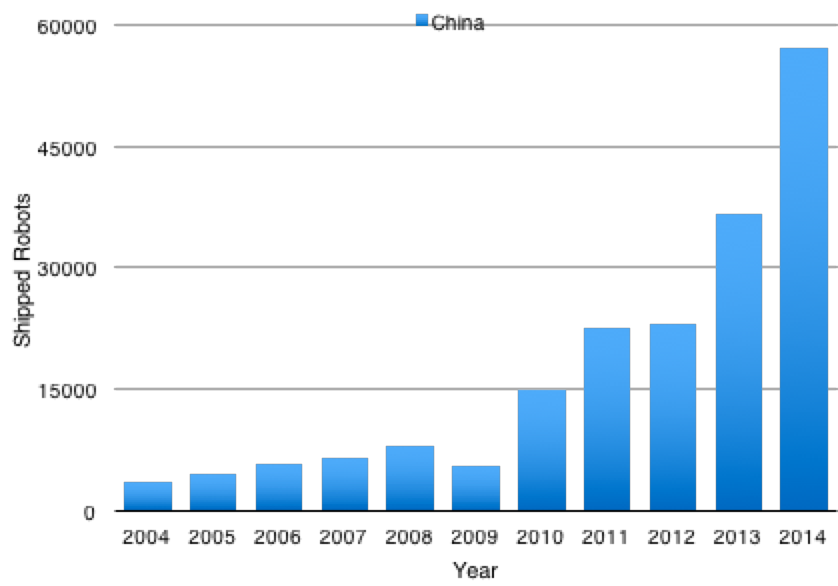

After the recession in 2009 some areas of the sector did a reset. As the recovery started back companies invested in new technology. This has resulted in China going from nowhere in robotics to being the largest market in the world, while Japan has seen limited growth over the last decade. For what sectors will we see a similar change in direction as we emerges from the 2020 downturn / pandemic?

Roadmap-2020

During 2020 we published the next version of the national robotics roadmap (ref). The roadmap brings together experts from industry and academia to consider growth opportunities and R&D needs to ensure continued economic growth. The roadmap points to major opportunities for automation as part of product customization, continued urbanization, and an ever aging society. Advances in new materials, sensors, machine learning, and user-interaction is paving the way for a new generation of robot applications across manufacturing, service, logistics, transportation, and healthcare. As we see a new administration early 2021 it will be interesting to see how/if science priorities are changing.

Economics

The stock market has seen tremendous growth over the last year despite the pandemic and the downturn during February and March. NASDAQ went up 41% during 2020, S&P 500 went up 15%, and Dow Jones Industrial Index 6%. Many people saw a big challenge in late March, but the market regained a lot of its momentum in the second half of the year.

Service, E-Commerce and new Energy did by far the best on the stock exchange, while cruise lines and oil companies fared the worst.

ROBO Global

As a co-founder of ROBO Global it was obvious to monitor the market closely, and pay special attention to the Exchange Traded Funds (ETF) sector.

ROBO Global has seen solid investments throughout 2020. The growth in logistics, healthcare, automation has generated a solid 43% YTD growth with across the various sectors.

ROBO was complemented by a healthcare investment during 2019. It would have been hard to find better timing. The HTEC fund has seen a 60% growth during 2020, as one would expect and the AUM is now well beyond $100M, and one would expect to see continued strong growth during

2021.

During 2020 a new fund focused on AI and Machine Learning (THNQ) was launched. The fund has seen a growth in value of 54% during the year. The second half of the year has been especially promising. During 2020 it was clearly shown how AI can be leveraged for optimization of logistics, quick drug discovery, real-estate optimization etc and it is clear that Artificial Intelligence and Machine Learning is a major part of our future society, so this is not surprising.

Science Community

Being a scientist / researcher during a pandemic is a different experience. We are used to spending a lot of time in meetings and at conferences. This year travel has been close to impossible. Consequently, meetings had to come to us. Doing remote meetings is not nearly as much fun and I am not convinced we have found the right model yet. We are by now used to pixelated video and sub-par audio, so volume went up and we accepted lower quality. During 2020 it became commonplace to see “strange video conference behavior” as part of commercials. It would have been difficult to imagine a year ago.

Still, science production is high. People are at home at lots of time spent in airplanes is not devoted to work in the home office. It is easy to set up 1:1 meetings between professors and students, but somethings are lost in video conferences. What will be the long-term impact on the community?

Taught two virtual classes during fall 2020. This was a lot more work that doing in person presentations and it is evident that the connection to students is very different from traditional classes. Presenting to 24 icons on a screen (where everyone has their video turned off) is much less motivating than discussing a subject with students in person. It takes a lot of work to prepare for these virtual classes and it will take time to get the model right.

An essential part of being part of the science community is social interaction, which has suffered during 2020. I think we all are looking forward to a time when we can socialize again.

R&D in a Post-COVID community?

An obvious question is how will the things evolve in a post-COVID world? It seems obvious that the educational system will slowly change to a model where engagement is life-long. For those of us in AI, Robotics, … the technology is changing at an exponential pace and there is a need for regular engagement rather than 3-year sprints. How will life-long education evolve? Could we imagine a subscription-based system where you sign up for 2-4 hours of continuing education for the rest of your life? Clearly, Coursera and Udacity have started a process in that direction, but for some domains, hands-on interaction is required a video lectures is not an obvious solution.

Others have engaged in problem-based education, where the skill and knowledge acquisition is driven by a life-long model to – learn to solve problems, learn to acquire knowledge and apply your skill set to address real-world problem. My alma mater – Aalborg University – is a leader in such an educational model and I see a need for many more to follow such a model. We do not need bit-sized education delivery, but an ability to educate people that can solve problems and acquire knowledge as the world evolves. This is especially important for areas with exponential growth.

Continuing engagement is also essential. Robotics Today (joint MIT/Stanford) and IFRR Colloquia are great examples of how the community has evolved to have weekly robotics seminars by world-class speakers broadcasted to everyone. Leading speakers could spend all their time traveling to universities to give one-hour tasks, this is a more effective mechanism for everyone to learn about state of the art, but clearly there is a need to complement with 1:1 engagement with leaders to ensure a broad model for engagement across the community.

Summary

The year 2020 has in many ways been the worst on record for most people. However, we have seen major technological progress, significant economic growth, and major changes in the academic enterprise. It will be interesting to see how we embrace these challenges and opportunities as we (hopefully) enter into a post-COVID era.

Wishing everyone a Happy New Year and all the best for 2021.